Following our overview of nonwoven technologies, this article provides a technical dissection of a modern needlepunch production line. For manufacturers and engineers, understanding these core components is key to optimizing output and product quality.

A needlepunch line transforms loose fiber into a dense, engineered fabric through mechanical entanglement. The integrity of the final product—be it for geotextiles, automotive interiors, or synthetic leather—is built upon the performance of each integrated section.

1. Fiber Preparation Stage: The Cornerstone of Quality

Automatic Feeding & Blending Systems: The process begins with the precise dosing and opening of raw fiber bales. Advanced systems ensure a homogeneous blend and consistent feed weight, which is the first and most critical step in avoiding final product variation.

Carding Machine: This is where the web is formed. The carding machine uses a series of rotating cylinders covered with specialized carding cloth to individualize fibers and lay them into a continuous, cross-lapped web. The precision of this web directly dictates the basis weight uniformity and mechanical properties of the final fabric.

2. Pre-Needling: Ensuring Process Stability

The web from the card is voluminous but has low strength. The Pre-Needle Loom provides initial consolidation. It gently compacts the web, giving it enough tensile strength to be transported through the subsequent, more aggressive main needle looms without web breakage—a common bottleneck. This stage is essential for high-speed production lines.

3. The Main Needling Unit: Where Fabric is Forged

This is the core of the line. Here, barbed needles mounted on a reciprocating board punch through the web, mechanically interlocking the fibers.

Needle Loom Technology: Modern looms offer high stroke frequencies for productivity and precise depth control for fabric design.

Needle Selection: The choice of needle (gauge, barb profile, crown type) is a critical engineering decision that affects everything from fabric surface texture and tensile strength to permeability.

Advanced Control Systems: PLC and HMI interfaces allow for precise control over parameters like punch density and depth, enabling the production of a wide range of fabric specifications on a single line.

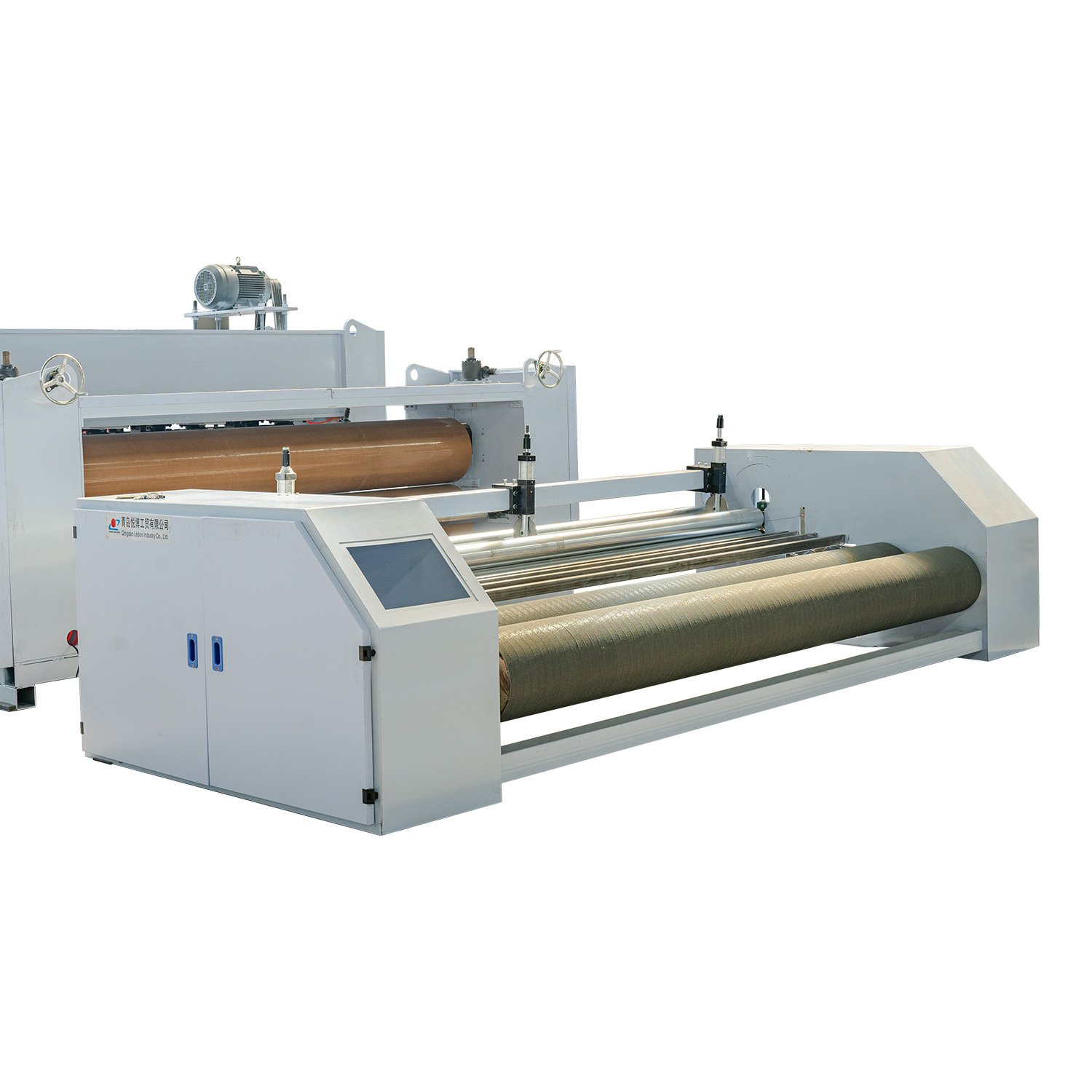

4. Winding: The Final Presentation

The final consolidated fabric is wound onto rolls. A state-of-the-art winding system is crucial. It must provide constant tension control to avoid stretching or distorting the fabric and ensure a perfectly cylindrical roll for trouble-free downstream processing.

Conclusion:

Investing in a needlepunch line is not merely about purchasing individual machines; it’s about integrating a synchronized system. The synergy between a high-accuracy card, a stable pre-needling stage, robust main needling units, and a precise winder is what separates a premium, consistent fabric from a mediocre one.